Marble is one of the most luxurious and durable natural stones used in construction and interior design. However, not all marble available in the market has the same quality. Buyers need to carefully inspect and test marble before purchasing to ensure that it meets both aesthetic and technical standards.

In this guide, we explain the key factors to check in marble quality so you can make the best investment.

🔍 1. Visual Inspection

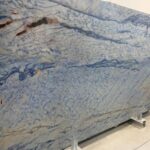

The first step in evaluating marble is to examine its appearance:

-

Color Consistency – High-quality marble should have uniform color without unusual patches.

-

Veining Patterns – Natural veins are expected, but excessive irregularity or large cloudy spots may indicate lower quality.

-

Surface Finish – Look for smoothness, shine, and polish. A high-quality marble should reflect light evenly.

🧱 2. Thickness and Size Accuracy

Check the dimensions of slabs or tiles:

-

Standard marble slabs are usually 18–20 mm thick. Anything thinner may break easily.

-

Edges should be straight and sharp. Uneven cuts or inconsistent thickness are signs of poor processing.

💧 3. Water Absorption Test

Porosity is one of the most important indicators of marble quality.

-

Place a few drops of water on the surface.

-

If water is absorbed quickly and creates a dark spot, the marble has high porosity and may stain easily.

-

Premium marble should have low water absorption.

🔨 4. Scratch and Hardness Test

Marble should resist scratches from everyday use.

-

Gently scratch the surface with a knife or coin.

-

If scratches appear easily, it is a softer marble and may not be suitable for flooring in high-traffic areas.

🎵 5. Sound Test

A traditional method to test marble quality:

-

Tap two marble pieces together.

-

Good-quality marble produces a clear ringing sound, while poor-quality stone makes a dull sound due to internal cracks.

🕳️ 6. Check for Cracks, Holes, and Fissures

Inspect carefully under natural light:

-

Look for hairline cracks that may weaken the stone.

-

Small holes (pores) indicate poor processing or weak stone structure.

-

High-quality marble should have minimum defects.

🧪 7. Chemical Resistance Test

Since marble is made of calcium carbonate, it reacts with acids.

-

Apply a few drops of lemon juice or vinegar.

-

If it bubbles or forms white marks quickly, the marble is very reactive and may not be suitable for kitchens.

📦 8. Certification and Standards

When importing or exporting marble, make sure the supplier follows international quality standards such as:

-

ASTM (American Standards)

-

ISO Certification

-

CE Marking (Europe)

This ensures the marble meets mechanical strength, durability, and finishing requirements.

✅ Conclusion

Checking marble quality before buying is essential to avoid costly mistakes. By following these simple tests — visual inspection, water absorption, scratch resistance, and certification checks — you can ensure you are investing in premium marble that lasts for decades.

If you are looking for high-quality Iranian marble for export, we provide a wide range of Carrara-style, Onyx, Travertine, and premium marble slabs with guaranteed quality and international standards.