From Mountain to Block: The Granite Mining Process in Iran Explained

The journey of a stunning granite slab, from a solid mountain to a polished centerpiece in a global project, begins with a complex and fascinating mining process. Iran, blessed with some of the world’s most abundant and diverse granite deposits, has perfected this art of extraction. The methods combine modern technology with geological expertise to yield the high-quality stone that architects and builders worldwide rely on.

At Iran Stone Market, we have deep roots in this process. As direct exporters, we understand every step that brings Iranian granite from the quarry to your project. This guide will walk you through the key stages of granite mining in Iran.

The Step-by-Step Process of Granite Mining

1. Prospecting and Geological Survey

Before any mining can begin, the search for viable granite deposits starts.

-

Geological Mapping: Experts survey the land to identify areas with the right type of granite, assessing its color, pattern, and structural integrity.

-

Core Sampling: Drill rigs extract core samples from deep within the bedrock. These samples are analyzed to determine the granite’s quality, vein structure, and freedom from hidden cracks or flaws.

2. Quarry Site Preparation

Once a suitable site is identified, the area must be prepared for safe and efficient mining.

-

Clearing and Overburden Removal: The top layer of soil, vegetation, and weathered rock (called “overburden”) is carefully removed to expose the fresh, valuable granite bedrock beneath.

-

Access Road Construction: Roads are built to allow heavy machinery to access the quarry site.

3. The Primary Cutting: Freeing the Granite Block

This is the most critical phase, where technology does the heavy lifting. The traditional method of drilling and blasting is almost entirely obsolete in modern quarries, as it causes too much waste and microfractures. Instead, the primary tool is the Diamond Wire Saw.

-

How it Works: A steel wire embedded with industrial-grade diamond segments is threaded through a pilot hole drilled into the granite. The wire is then connected to a large, motorized pulley system.

-

The Cutting Action: As the wire spins at high speed, the diamonds abrade the granite, creating a clean, precise cut with minimal stone loss. This method can cut vertically and horizontally, isolating massive granite blocks from the mountain itself.

4. Block Lifting and Transportation

Once a block is completely freed, it is ready to be moved.

-

Undercutting: Specialized machinery is used to undercut the block, separating it from the quarry floor.

-

Lifting: Massive cranes or heavy-duty excavators with rock grabs carefully lift the multi-ton block onto a heavy-duty truck. These blocks can weigh anywhere from 20 to 40 tons.

5. Primary Processing at the Quarry Yard

At the yard adjacent to the quarry, the raw blocks undergo initial preparation.

-

Inspecting and Grading: Each block is inspected for color consistency and structural flaws.

-

Trimming and Squaring: The blocks may be trimmed with smaller diamond wire saws or giant saws to create more uniform, squared-off shapes that are easier to transport and process further.

6. Transportation to Processing Plants

The squared blocks are loaded onto trucks and transported to advanced processing plants. Here, they will be sliced into slabs, polished, and finished according to market specifications before being shipped worldwide.

Why Iran’s Granite Mining is So Effective

The success of Iran’s granite industry is built on several key factors:

-

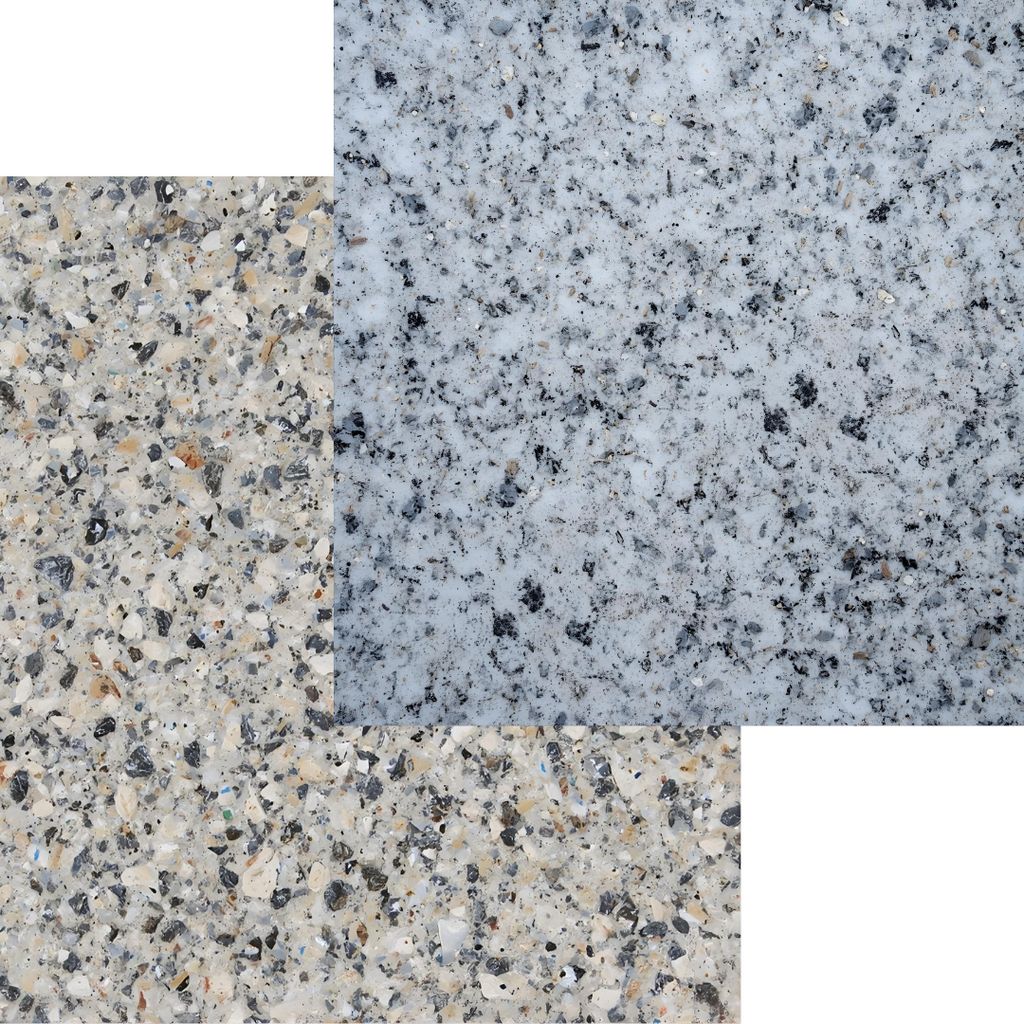

Abundant Reserves: Iran possesses vast and varied granite deposits, from the cosmic Black Galaxy to the profound Absolute Black.

-

Adoption of Modern Technology: Leading quarries use state-of-the-art diamond wire saws and drilling equipment, which maximize yield and minimize waste.

-

Skilled Labor: The industry is supported by generations of experienced quarry masters and technicians who understand the stone intimately.

-

Focus on Quality: The careful, non-explosive extraction process ensures the granite’s structural integrity is preserved, resulting in stronger, more beautiful slabs.

Our Role at Iran Stone Market

As a direct exporter, our involvement begins at the source. We don’t just buy finished slabs; we are involved in the process from the block stage.

-

Block Selection: We work directly with quarries to select the finest blocks based on color, grain, and quality.

-

Quality Control: We monitor the process to ensure the stone meets international standards from extraction to loading.

-

Efficient Supply Chain: Our deep understanding of the mining process allows us to guarantee a reliable and consistent supply for our global clients.

Build with Stone You Can Trace

Understanding the journey of granite mining highlights the value and effort behind every slab. It’s a process that transforms raw, ancient stone into a material of modern luxury and endurance.

When you source granite from Iran Stone Market, you are choosing a product of a refined and responsible extraction process.

Contact us today to learn more about our granite varieties and how we can supply the perfect stone for your next project.