Marble is one of the most luxurious and timeless natural stones used in construction and design. From flooring and countertops to monuments and sculptures, marble has always been admired for its beauty, durability, and elegance. But have you ever wondered how marble goes from a mountain quarry to the polished slabs you see in showrooms?

In this guide, we’ll explain the step-by-step process of quarrying and processing marble, from extraction to the final polished slab ready for installation.

1. Marble Quarrying: Extracting the Blocks

The journey of marble begins in the quarries, which are often located in mountainous regions rich in limestone deposits. The process involves:

-

Surveying & Planning: Experts identify the best area to extract high-quality marble with minimal cracks and impurities.

-

Cutting the Blocks: Using diamond wire saws, chain saws, or drilling machines, large blocks of marble are carefully cut from the quarry wall.

-

Splitting the Blocks: Hydraulic cushions or small controlled explosives are sometimes used to separate the blocks.

-

Transporting the Blocks: The massive blocks, which can weigh 20–30 tons, are lifted by cranes and transported to processing plants.

2. Marble Block Transportation

Once extracted, the marble blocks are moved from the quarry to processing factories. This requires heavy trucks and specialized equipment since the blocks are extremely heavy.

3. Block Dressing

Before cutting, the blocks are dressed to remove irregular edges. This step ensures a uniform shape for easier handling and cutting.

4. Marble Block Cutting

The blocks are then cut into slabs or tiles using different machines:

-

Gang Saw Machines: Use steel blades with abrasives to cut multiple slabs at once.

-

Diamond Wire Saws: Provide precise cutting with minimal waste.

-

Block Cutters: Used for smaller blocks, producing marble tiles.

5. Marble Slab Polishing

After cutting, the rough slabs are polished to enhance their shine and color. This process involves:

-

Grinding with coarse abrasives to smoothen the surface.

-

Polishing with finer abrasives to achieve a glossy finish.

-

Adding resins or sealants to strengthen the stone and fill tiny cracks.

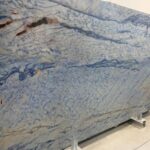

6. Quality Inspection

Every slab undergoes a strict quality check to ensure it meets international standards. Defects, cracks, and color variations are carefully inspected.

7. Packaging and Shipping

Finally, marble slabs and tiles are packed in wooden crates with protective materials to prevent damage during transport. From here, they are shipped to distributors, contractors, and buyers worldwide.

📌 Conclusion

The journey of marble, from quarry to polished slab, is a combination of engineering, craftsmanship, and technology. Each slab of marble tells the story of millions of years of geological formation and the careful hands that shaped it for modern use.

Whether used in flooring, kitchens, bathrooms, or luxury projects, marble remains a symbol of beauty and durability.